Tokyo and Shanghai,

Fujitsu Limited, Fujitsu (China) Holdings Co., Ltd. (collectively “Fujitsu”), and INESA (Group) Co., Ltd.(1), a large-scale, state-owned company in China that provides smart city solutions, today announced that they are collaborating on a Smart Manufacturing Project known as “Made in China 2025,”(2) a strategic framework which aims to strengthen competitiveness in manufacturing.

In response to the rapid changes in corporate business models and the market environment, the government of China has set forth “Made in China 2025”, which aims to combine cutting-edge ICT with manufacturing, shifting China from a manufacturing giant that mass-produces products to a manufacturing powerhouse that focuses on production quality. In the midst of this effort, using their abundant experience in the ICT and manufacturing fields, Fujitsu and INESA Group are jointly promoting their Smart Manufacturing Project, contributing to realizing the “Made in China 2025” plan.

As a member of a group of large-scale, state-run companies under the jurisdiction of the State-owned Assets Supervision and Administration Commission of Shanghai Municipal Government, INESA Group has a history in the electronics manufacturing industry of more than fifty years. In order to adapt to the innovations of recent years, INESA Group, while manufacturing, is driving the development of the information industry, and has established the strategic goal of contributing to the building of smart cities as its business model, working to create a new industry that fuses ICT and manufacturing.

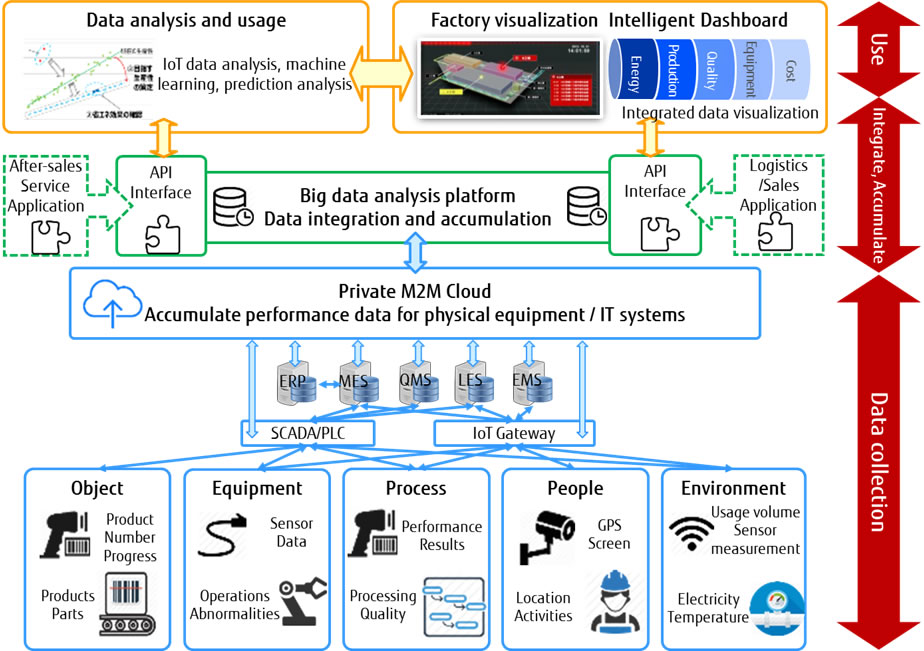

At a color-filter manufacturing plant of INESA Display Materials Co., Ltd., an INESA Group company, Fujitsu established a plan to turn the plant into a smart factory suited to current operations, by studying current processes and issues. Based on information from existing automated production lines and manufacturing management systems, Fujitsu is connecting the entire manufacturing process, including product manufacturing processes and production line placement, with technologies, such as big data and IoT. This is to achieve digital transformation, building a system that visualizes the efficiency of the factory with the use of tools such as Fujitsu’s sensors, network technologies, a dashboard solution, and a big data analysis platform, to advance INESA Group’s move toward smart manufacturing.

The three companies began this project in January of 2016, and aim to complete it in 2018. In the first stage of this project, Fujitsu organized and improved INESA Group’s existing information systems, advanced the deployment of IoT in the factory, and built a big data analysis platform. As a result, it has become possible to share data within the factory and visualize operations in real time. The constructed platform will support higher levels of factory intelligence in the future.

The specific initiatives implemented under the current project are as follows: